The lowly beer six bottle carrier. It hard to believe that a device with such little substance can reliably carry so much weight; especially if you consider that the weight is made up of 6 glass bottles filled with beer. This is the mighty six bottle beer carrier. How is this possible? The secret is in the exquisite structural engineering used in its design and in its paperboard construction. What most people call cardboard we in the packaging industry call paperboard. The paperboard used to make our White Six Bottle Carriers, P5244, is a product called SUS® (Solid Unbleached Sulfate). It is .018 of an inch thick. It is treated to ensure it can withstand moist storage conditions and is strong enough to hold bottles of beer.

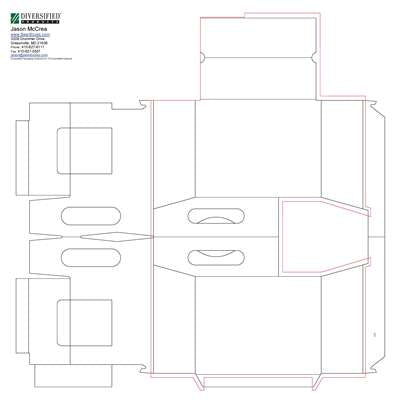

The lowly beer six bottle carrier. It hard to believe that a device with such little substance can reliably carry so much weight; especially if you consider that the weight is made up of 6 glass bottles filled with beer. This is the mighty six bottle beer carrier. How is this possible? The secret is in the exquisite structural engineering used in its design and in its paperboard construction. What most people call cardboard we in the packaging industry call paperboard. The paperboard used to make our White Six Bottle Carriers, P5244, is a product called SUS® (Solid Unbleached Sulfate). It is .018 of an inch thick. It is treated to ensure it can withstand moist storage conditions and is strong enough to hold bottles of beer.Before you recycle an empty carrier pull it apart gently and examine its features. What you will find is a design similar to the one pictured below. It is amazing that the devices that can securely and reliably hold six heavy glass bottles of beer are so slim and lightweight. A must in the bottle packaging industry as broken glass and spilled alcohol is a dangerous mess to have to clean up.

This cutting die is made up of a plywood panel which is embedded with steel blades. There are several types of blades: cutting, creasing and perforated (See die outline above). The printed sheet is fed into the die cutter and it is pressed into the cutting die which cuts, perforates, scores, and strips out the unwanted cut scraps of paperboard from the sheet. This process sets up the sheet for what comes next, folding and gluing.

The automatic folding and gluing operation is fascinating. From a hopper of stacked die cut sheets the sheet is fed into the gluer. The sheet moves rapidly through the gluer and as flaps are folded glue is applied and the appropriate flap folds into place right on top of the glue. The six pack beer carrier is now flat and held in place just long enough for the glue to dry. Ultimately the six packs are packed into cases and the cases are stacked on pallets ready to ship.

So now you know the story of the mighty beer six pack carrier, an engineering marvel that performs reliably time after time.